Warehouse Management Systems

A central, efficient and useful warehouse management system database designed and used with other technologies such as static and mobile barcode readers.

|

Sales Order, Purchase Order integration |

|

|

Picking, Putting Away, Confirm Despatch |

|

Stocktakes |

|

Barcode Readers, (static and mobile) at key points of your warehouse |

|

Improved information flow - true-to-life modelled software, perfectly modelled, no more interpretting the system |

|

Auto print labels (mobile printers, static printers in key positions) |

|

Validate data is correct, using software that enforces business rules/protocols/processes by preventing further action until the correct expected barcodes are scanned. Forcing staff to seek help from a supervisor, rather than just doing what they want. |

|

Track any business entities, Asset Management, Asset Maintenance Schedules |

| |

|

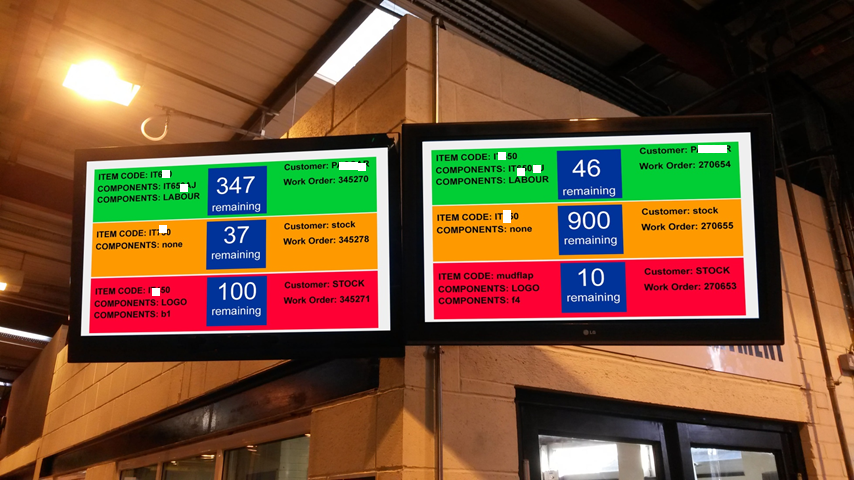

- Large Work Summary Screens. 1, 2, or 3 summary screens per input station. Each work input station and summary screen station are placed in Key Visible Locations around the business.

- Input Stations are optionally placed near summary screens and used to record work completed. As part of your business processes.

- Where wireless barcode readers are not necessary, for example.

- Immediately updating the rest of the organisation on a job's progress

- In reception

- Showing visitors where their work is up to while they wait, (in certain scenarios)

- In Sales and processing

- Showing the staff what is ready for despatch or for invoicing

- Showing what was last invoiced.

- Showing delays

- In Warehouse, in packing, in despatch

- Auto print (to the nearest printer, or a wireless printer) a Work Order Sheet including a barcode, when a Work Order is started or turns green

- Summary screen showing what’s being worked on right now, what’s nearly finished, what’s next, what’s moving quickly, what’s moving slowly

- Showing picking jobs waiting to be put in despatch location, showing putting away jobs waiting from Goods Inward areas

- In Goods Inward

- Showing what jobs are waiting for material in

- Auto print GRN label/sheet with barcode

- Communicating with other screens around the warehouse when items are ready to be put away

- Each screen shows only what is needed by that department

- a ‘What’s Next?’ approach

- a Supervisor console for changing work order priorities, order, sequence

- Access through your internet browser

- Add extra value and quality to your existing ERP or MRP. Sage ERP 1000, Line 200, the list is endless.

- Visible processes everywhere, instantly

- View any summary screen from any PC on your network via your internet browser – see what’s going on.

- Custom built to tie in with your business’s processes every step of the way

- Efficient, Cost efficient, excellent return on investment

Wireless Barcode Readers

- Work with the WMS-Pro system and your ERP/MRP

- A barcode app issuing jobs to workers instantly

- Picking / Stock take / Putting away

- Potentially a Paper Free System!

- Reduce Carbon Footprint at the same time as adding extra value to your existing MRP system.

- a ‘What’s Next?’ approach for the operator. Efficient for supervisors and managers. No more walking the corridors for every job or issue that arises. Just click in your supervisor console and the jobs are broken down and issued out automatically with predetermined logic.